Three major problems hinder the development and upgrading of domestic textile machinery industry

key word: Three major problems hinder the development and upgrading of domestic textile machinery industry

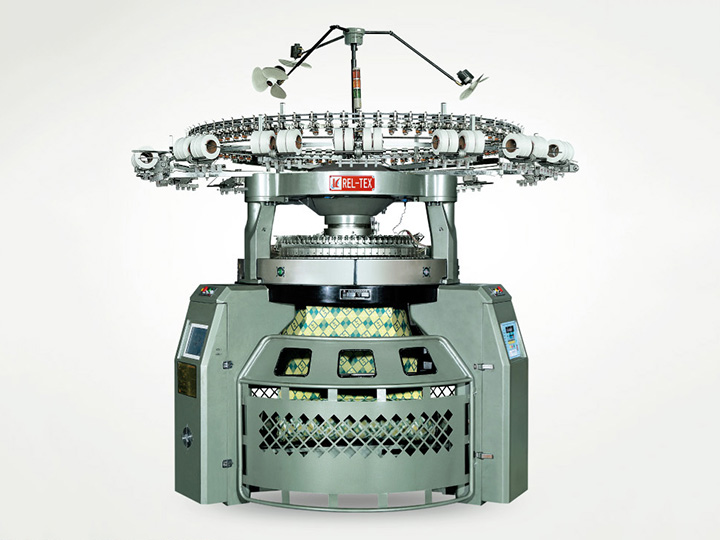

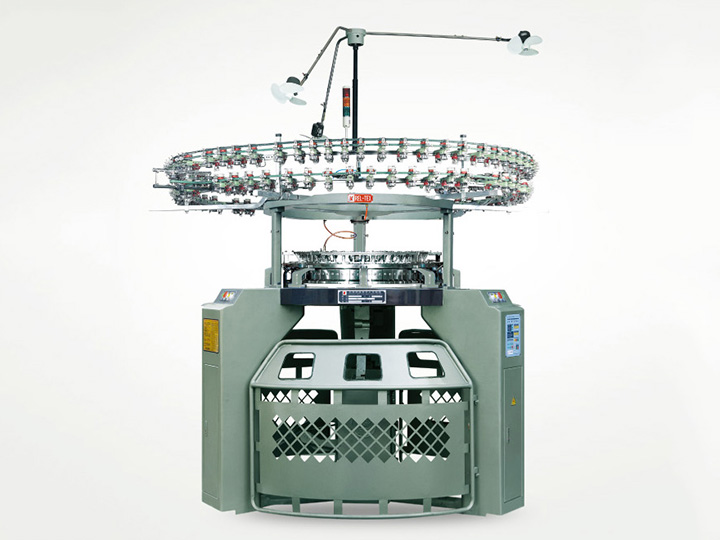

China's textile industry is in a critical period of transformation and upgrading. In just a few years, a large number of new electromechanical integrated textile equipment have been emerging, which is welcomed by users. However, it is undeniable that the textile industry has experienced a period of sustained development and growth, and the overall situation is slightly depressed. As a part of the textile industry, the situation of textile machinery is not optimistic.

In order to reverse the adverse situation and strengthen the development momentum, China's textile machinery industry needs to solve the following three problems.

Problem 1: Mechanized imitation

At present, there is a big gap between domestic textile machinery and foreign equipment in terms of stability, failure rate, reliability, etc. Compared with the running in period of foreign equipment, which is generally half a month, the failure rate of domestic equipment is still relatively high after several months or even more than half a year. In addition, the author once heard that the sales manager of a textile mill described the process of their development of the comber. First, a more advanced comber was mapped on the spot in a cotton mill, and then the comber could be manufactured and put on the market in less than half a year. This may be exaggerated, but it also reflects from the side that some domestic manufacturers only imitate mechanically, without the process of digestion, absorption, investment and research. How can we produce high-quality machines? In fact, in the context of global division of labor, independent innovation is a comprehensive process closely related to system integration, processing equipment and technology, management level, etc. The gap between China's textile machinery equipment and foreign countries is not only the gap of technological invention, but also the overall lag of technology, talents, management, etc.

Problem 2: One sided exaggeration of product functions

In order to obtain orders and seize the market, some textile machinery enterprises, by configuring accessories and equipment that do not meet the original design requirements, take the high level reached in the experiment as a normal indicator to promote, and unilaterally exaggerate the function of the equipment. Taking spinning automatic doffer as an example, some machines claim that it takes 3-4 minutes to collect each row of yarn, and the head retention rate is promised to be more than 97%, but the actual yarn arrangement takes 4.5 minutes on average, and the head retention rate is less than 96%. The author has gone through some enterprises, and the overall efficiency of the new equipment purchased is not as expected due to the poor quality of the components and equipment. Maintenance work is heavy, and machine and material consumption is much higher than expected. This invisible loss is huge. This disguised fraud is irresponsible for users, but also for themselves.

In addition, in the process of introducing new products and equipment of textile machinery to the market, there is still a phenomenon of nonstandard operation. It is understood that the new equipment exhibited by textile machinery enterprises at the European International Textile Machinery Exhibition will not be introduced to the market until it has been tested for at least two years in the experimental factory or the enterprise factory with which it cooperates. At present, there are still many domestic textile machinery factories that, intentionally or unintentionally, directly regard cotton mills as experimental factories, and use lower than market prices as bait to sell newly designed but untested equipment. The problem is that the prototype is not equal to a commodity. The prototype has not undergone fatigue tests such as reliability, stability and failure rate for a considerable period of time in the experimental factory or the affiliated yarn factory, and it is often put on the market hurriedly. The configuration of the prototype is inconsistent with the configuration put on the market. After it is put into production, it will not only fail to achieve high efficiency, but also transfer the risk to the user, which will cost the user a lot of manpower and material resources.

Problem 3: Equipment cannot keep up with the host

Some textile machinery factories have some problems in the research and development of equipment, or how to transform samples into practical products that satisfy users, such as nonstandard design, lack of attention to innovation, and failure to systematically coordinate the functions, materials, processes, etc. of each component.

Firstly, the quality of key components is not up to standard or the selection is improper, and the machining and assembly accuracy cannot meet the design requirements. The quality of equipment and components directly determines the quality of the whole machine. The equipment configuration is not in place and there is no standard. It is only determined according to the price agreed with the customer. If the price is high, the configuration is good; Low prices, poor configuration. Secondly, the technology of textile machinery and its supporting facilities lags behind. According to the author's understanding of the textile market, at present, there are three aspects of lag: first, the lag of equipment after high production is more prominent;

Second, the maintenance methods of high-end equipment can not keep up with the requirements; Third, the maintenance focus of new high-speed equipment and the fueling specification lag behind. Third, the supporting technologies related to the process of rolling stock are not in place, so that the process can not be really stable rolling stock for a long time. Textile machinery factories are often used to the production of host machines and seldom study the production technology and process software of popular products on the market. In fact, in some cases, the equipment performance is not good, but there is no reasonable process configuration according to the customer's production raw materials. Therefore, to some extent, textile mills should also employ textile technologists at the level of ^ to assist in textile machine design.